Hi there,

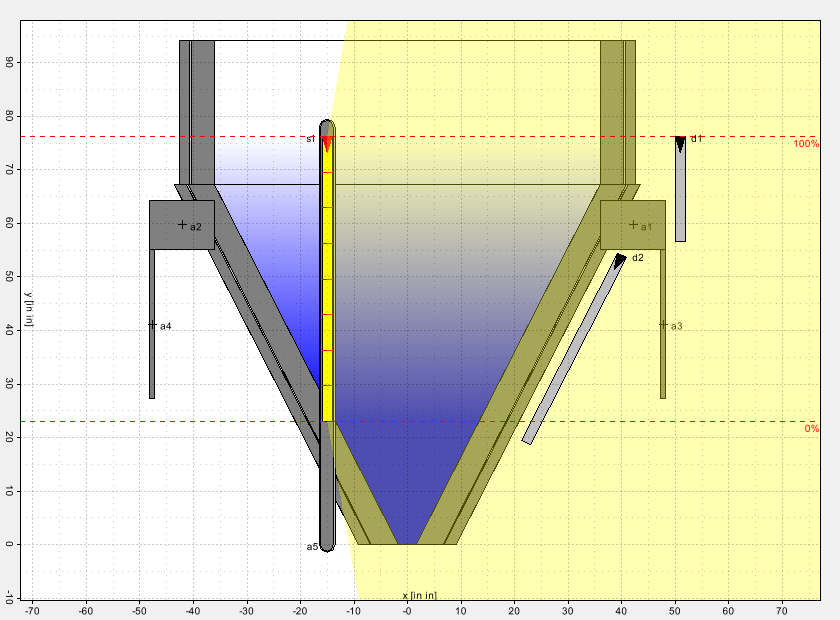

I am writing a web application for simulating radiometric measurement systems consisting of a tank filled with various liquids, gamma sources (possibly in curved dip tubes) and detectors mounted on the tank.

Since any of those things can be quite complex, I would like to use CAD models and import them as G4TesselatedSolid, e.g. by use of CADMesh.

Now, since any of these components could be inside the tank and since there are multiple layers of liquids in the tank, I also need Boolean Solids, mainly subtractions, in order to avoid overlaps. For example, I would subtract the dip tube from the tank and all liquid layers, before placing the dip tube in the world volume. Likewise, I would subtract various tank walls from each other, in order to avoid numeric problems related to curvature discretization of the various CAD models and in order to to ensure water-tightness in the model.

As far as I understand it, any tracking for a Boolean Solid is done by executing the tracking for each operand and then applying the boolean operation on the results. How does that work with G4TesselatedSolid? Does that mean that all facets/triangles are involved in the boolean operation?

Is it, performance-wise, a bad idea to combine G4TesselatedSolid with Boolean Solids? Does anybody have any experience with this on a large scale with big CAD models and many boolean operations?

As a side note: This is a rather big project with a high degree of automation and I cannot foresee yet, how big the models and meshes involved can become.