Good morning/evening geant4 guru!

I need to simulate the following geometry:

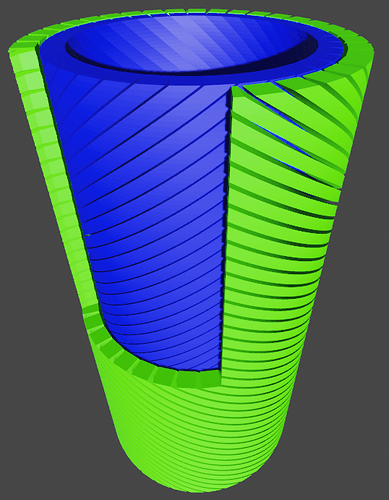

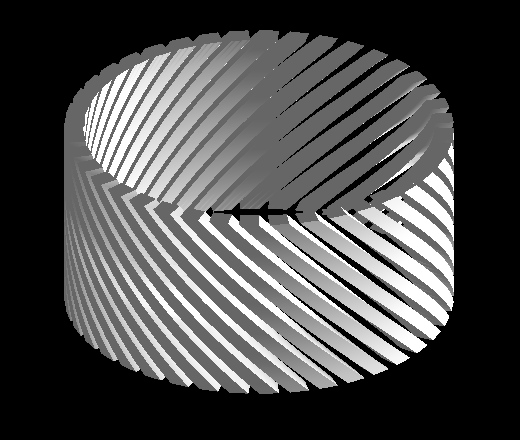

scintillating square fibers coiled in the shape of a cylinder but running at an oblique angle. Basically the fibers follow a helix. so I guess the geometry I’m looking for is a “square helix”. We are talking about 250-500 microm square fibers wound along a 5cm diameter cylinder and 30cm long.

To top it off there are going to be two cylinders with fibers with different orientations.

Added a picture to help understand the problem

Clearly the cutout in the green fibers is just to better see the blue fibers. ![]()

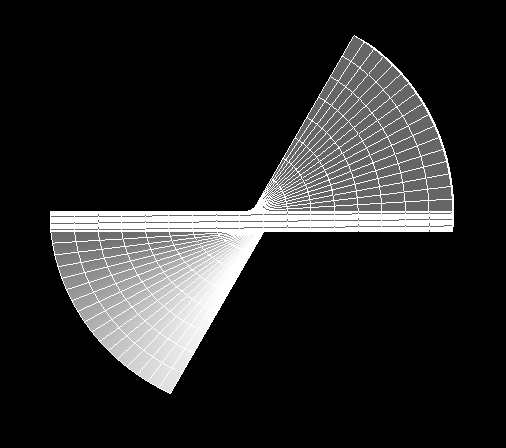

Clearly I only need a single fiber and then I can duplicate and rotate along the cylinder axis. but how do i create the shape?

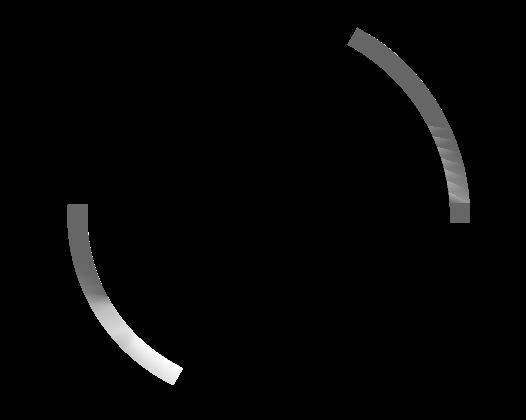

I was hoping TwistedTubs might do the trick (even if it’s not a perfect square it would be “close enough”) or something similar; ChatGPT suggests using G4ExtrudedSolid (but the examples it gave me are mostly broken…); I can try to glue different sections; G4TessellatedSolid might be an option. This would involve quite a lot of C++ to define triangles, but it can be done…

Or do I just need to bite the bullet and go with CAD->GDML

Since the geometry isn’t final, I’d like to have a “parametric” solution and the cad on this side would be slow. But it seems to me that there is no practical way to define my geometry.

Opinions? Thanks a lot!

Cheers from Italy

Additional info: the scintillating part is already taken care of. I’m already running a simulation with fibers. I’m currently using Geant4 11.1.1 but if needed I can downgrade. My code was working fine a week ago with 10.7.4